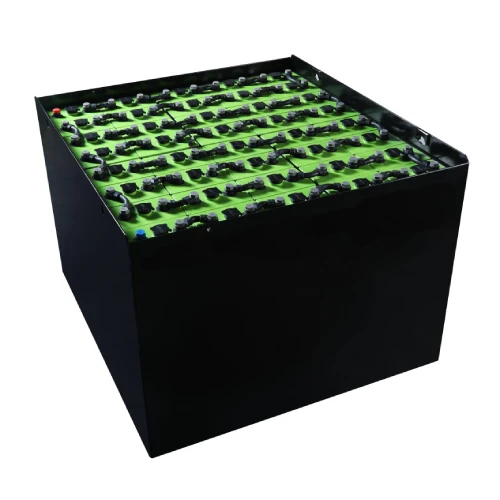

Forklift & Warehouse Equipment Batteries

- Authorised dealer for ET power brand traction batteries

Power For Tomorrow Today

Eternity Technologies – A global leader in the industrial battery market providing world-class products for Motive Power and Network Power applications.

Eternity Technologies based in the dynamic and vibrant United Arab Emirates have developed a state-of-the-art manufacturing facility at a cost of about Rs.550 Crore Ranked among the top five factories in the world of motive Power along with batteries for industrial application.

Eternity Technologies utilises the latest design, manufacturing process and customer-focused management systems to not only meet the needs of the global power market but define them for the future.

Certified to ISO 9001, ISO 14001 and OHSA 18001, the manufacturing facility meets the most stringent international standards for Quality, Environmental Management and Health & Safety.

State of the art assembly unit is located at Bhiwandi near Mumbai. Eternity Technologies import all cells from their parent plant in the UAE and assemble them as per technical standards of Eternity in compliance with world renowned original equipment manufacturers.

Available in DIN, BS & BCI dimensions, this range of flooded lead acid batteries are suitable for all your traction needs.

Long Life

Low Maintenance

Maintenance Free

- Low temperature Facilities

- Specifically for use in clean environments

- VNA Applications

- Cold Storage Applications

- Ground Support Equipment

- AGV Applications

- Batteries for all Applications

- Forklift Trucks

- Electric Vehicles

- Cleaning Machines

- Lifting Platforms

- Road Vehicles / Tow Tractors

Lithium-Ion Batteries Engineered for Performance

Experience the next level of energy efficiency and reliability with advanced lithium-ion battery systems. Designed for high-demand industrial environments, these batteries deliver longer run times, faster charging, and lower maintenance—maximizing productivity while reducing operational costs.

Why Lithium-Ion (LiFePO4) is the Smarter Choice

High energy density.

High life expectancy.

Wide operating voltage range

Zero Maintenance

Quick recharge capability

Quick recharge capability

High Life cycles.

High Life cycles.

Long battery life, even in high ambient temperature applications

Unlike conventional batteries, no sulphation or grid corrosion hence no risk of sudden death.

No emission of toxic Gasses.

No chemical Hazards.

Wide operating temperature range.

Points to be Considered

CHARGING HABITS

Fast or Partial charging can ruin a Conventional battery. Whereas Lithiumlon batteries are flexible enough to adapt to variable charging habits without harming battery life and durability.

CHARGING TIMЕ

The Charging time required for conventional batteries, ranges from 6-8 hours.Whereas Lithium lon Batteries can be charged quicker within 2-3 hours, depending on battery capacity & usage.

WEIGHT

Lithium lon Batteries are 3 to 4 times lighterthan conventional batteries, thereby reducing the load on vehicles.

MAINTENANCE

Mandatory operational & maintenance costs such as Space for charging, gas disposal & water demineralization. Lithium lon on the other hand comes with negligible maintenance costs.

AUTOMATIC DISCONNECTION

With the newer technologies, it is possible to disconnect charging in Lithium lon Batteries once the charging is comp

ENABLING OF BMS

Systemsare one ofthe most efficient features of Lithium Ion Batteries which make sure that the user knows how the batterys performing withanalyeed and monitored data.

Designed to amplify your vehicle's performance

Compact Size

Less weight.

BMS protection for each battery pack.

- High voltage protection.

- Low voltage protection.

- High current charge and discharge protection.

- Over-temp protection.

- Short circuit Protection. Communication

Communication (Optional)-CAN,RS485,Bluetooth.

Protection - Waterproof

What is a Battery Conversion Kit?

A specialized solution designed to replace traditional lead-acid batteries in forklifts with advanced lithium-ion technology. This retrofit involves installing a modular lithium battery system, integrating a compatible charger, and ensuring seamless communication with the forklift’s existing systems. The result is a forklift that operates more efficiently, with reduced maintenance needs and enhanced performance.

Why Use a Battery Conversion Kit in Forklifts?

Forklifts are integral to material handling operations, and their performance directly impacts productivity. Over time, traditional lead-acid batteries can degrade, leading to reduced efficiency and increased maintenance costs. Converting to a lithium-ion battery system offers several advantages:

Extended Operational Hours: Lithium-ion batteries provide longer run times, reducing the need for frequent recharging.

Opportunity Charging: These batteries can be charged during breaks without affecting their lifespan, ensuring forklifts are always ready for use.

Reduced Maintenance: Unlike lead-acid batteries, lithium-ion batteries require minimal maintenance, eliminating tasks like watering and equalizing charges.

Compact Design: The smaller size of lithium-ion batteries frees up valuable space in your facility.

Drop-In Lithium Battery Replacement for Lead Acid Battery

Benefits of Battery Conversion Kits

Enhanced Efficiency

Lithium-ion batteries have higher energy conversion rates, meaning more of the energy you pay for goes directly into powering your forklift.

Cost Savings

With longer lifespans and reduced maintenance requirements, businesses can achieve significant cost savings over time.

Environmental Impact

Lithium-ion batteries are more environmentally friendly, producing fewer emissions and reducing the frequency of battery replacements.

Improved Safety

The reduced need for battery maintenance and the absence of hazardous materials like sulfuric acid enhance workplace safety.

Space Optimization

The compact nature of lithium-ion batteries allows for better utilization of warehouse space.

Consistent Power Output

Lithium-ion batteries deliver a steady voltage throughout the charge cycle, ensuring consistent performance from start to finish. This leads to smoother forklift operation and reduces strain on motors and electronic components.

Sunray Material Handling Pvt Ltd Jigani, Bangalore

Our state-of-the-art workshop located in Jigani Industrial Area, Bangalore, is fully equipped to handle all kinds of repair, refurbishment, and training needs. We offer both on-site and in-house services, and also conduct certified training for MHE operators, technicians, and engineers to ensure safety and efficiency.